"Bandit" (2bandit)

"Bandit" (2bandit)

08/29/2013 at 21:02 • Filed to: emma

2

2

40

40

"Bandit" (2bandit)

"Bandit" (2bandit)

08/29/2013 at 21:02 • Filed to: emma |  2 2

|  40 40 |

I get to start assembly on Saturday. Any tips on assembling an engine? Should I put the cam in first? Extra info: I'm putting a new cam/lifters, new timing gears, and a new harmonic balancer in.

For Sweden

> Bandit

For Sweden

> Bandit

08/29/2013 at 21:03 |

|

I recommend putting the parts in the right places, but that's just me.

Bandit

> For Sweden

Bandit

> For Sweden

08/29/2013 at 21:05 |

|

... and don't end up with too many left over pieces.

dogisbadob

> Bandit

dogisbadob

> Bandit

08/29/2013 at 21:06 |

|

oh just put whatever fits on it wherever it fits :p

dogisbadob

> Bandit

dogisbadob

> Bandit

08/29/2013 at 21:06 |

|

you're welcome?

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 21:06 |

|

Take your time. Take some notes or have a checklist for torquing bolts. Use assembly lube. Check bearing clearance with a plastigauge.

Bandit

> dogisbadob

Bandit

> dogisbadob

08/29/2013 at 21:08 |

|

Summit Racing <3 Bandit's money.

pdthedeuce

> Bandit

pdthedeuce

> Bandit

08/29/2013 at 21:08 |

|

(alright, here comes a softball )

go slow , and use lots of lube .

Bandit

> GasolineLollipop

Bandit

> GasolineLollipop

08/29/2013 at 21:08 |

|

Shall do. Thank you.

TheLOUDMUSIC- Put it in H!

> Bandit

TheLOUDMUSIC- Put it in H!

> Bandit

08/29/2013 at 21:09 |

|

Assemby lube is your friend

Bandit

> pdthedeuce

Bandit

> pdthedeuce

08/29/2013 at 21:09 |

|

It's my first time!

TheLOUDMUSIC- Put it in H!

> For Sweden

TheLOUDMUSIC- Put it in H!

> For Sweden

08/29/2013 at 21:10 |

|

Y U all of a sudden GREY?

GhostZ

> dogisbadob

GhostZ

> dogisbadob

08/29/2013 at 21:19 |

|

"It came as a V8. I don't even know how it ended up as a flat-6.

desertdog5051

> Bandit

desertdog5051

> Bandit

08/29/2013 at 21:37 |

|

I take it you already installed the crank. (lots of assembly lube, I hope) Pistons & rods next, (rings indexed to manufactures specs) followed by cam then lifters and heads and so forth. Torque everything to specs. Critical you have a torque wrench for engine assembly. And as Gasoline said, rod and main clearance with Plastigauge. End play on the crank is also important. There is a lot more to assembling a motor than just bolting parts back together. Good luck.

Bandit

> desertdog5051

Bandit

> desertdog5051

08/29/2013 at 21:42 |

|

The bottom end is staying stock. I didn't remove the pistons or crank. Thanks for the info.

matthewklein220

> Bandit

matthewklein220

> Bandit

08/29/2013 at 21:42 |

|

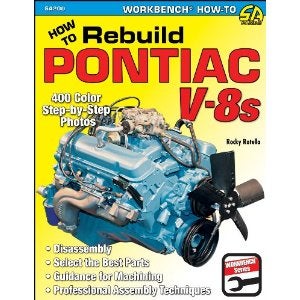

BUY THIS BOOK. Tells you what to put, in what order, tips, and also what setting to torque most (if not all) the bolts to. My dad has three copies and we lend them out to friends whenever an engine is going together.

Bandit

> matthewklein220

Bandit

> matthewklein220

08/29/2013 at 21:43 |

|

I should get that. I have a haynes and a chiltons, but that book seems more useful.

matthewklein220

> Bandit

matthewklein220

> Bandit

08/29/2013 at 21:46 |

|

Another book for down the road (when Emma needs a stronger heart) I suggest the How-To BuilD Max Performance Pontiac Engines by Jim Hand. The guy basically tells you how to make 500 hp using a staggering number of factory parts. It's by the same publisher.

matthewklein220

> Bandit

matthewklein220

> Bandit

08/29/2013 at 21:47 |

|

Also, amazon link (just to make things easier):

http://www.amazon.com/How-Rebuild-Po…

Bandit

> matthewklein220

Bandit

> matthewklein220

08/29/2013 at 21:56 |

|

Wow, that's relatively cheap. Thanks for the link.

matthewklein220

> Bandit

matthewklein220

> Bandit

08/29/2013 at 22:01 |

|

Anything for a fellow Firebird driver!

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 22:09 |

|

Did you/are you going to check the main and rod bearings?

Bandit

> GasolineLollipop

Bandit

> GasolineLollipop

08/29/2013 at 22:11 |

|

I didn't know those need checking... (how does one go about checking them?)

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 22:19 |

|

Reference http://forums.highperformancepontiac.com/70/8990895/dri…

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 22:27 |

|

Its a bunch of work. If you feel confident without rebuilding the bottom end then thats fine. I always check everything when its apart. I usually put in new bearings if everything measures out.

Bandit

> GasolineLollipop

Bandit

> GasolineLollipop

08/29/2013 at 22:40 |

|

Visually the bottom end looked great, the motor has pretty low (60k) miles for being 40 years old. The cylinder walls and pistons look brand new. This time I shall not build the bottom end, in the future when the engine needs a rebuild (or I become hungry for more power) I will rebuild the whole block.

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 22:50 |

|

Do you have a handle for the cam? As it goes in you lose leverage over the cam. The handle helps putting the cam in. A simple rod welded or bolted to a plate that bolts to the front of the cam will work too. You may even be able to rent one at the auto parts store. You don't want to knick the cam bearings.

Bandit

> GasolineLollipop

Bandit

> GasolineLollipop

08/29/2013 at 22:57 |

|

I do not, I should be able to use some long bolts though eh? Just crew them into the camshaft? I could also try and weld one up at school. I am very worried about harming my bearings, I should probably use plenty of lube.

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 23:13 |

|

The cam will try to hang up on all the lobes. Rent a handle at autozone. Soak the lifters in engine oil if they are hydraulic.

Bandit

> GasolineLollipop

Bandit

> GasolineLollipop

08/29/2013 at 23:17 |

|

I experienced that removing the old cam. The lifters are hydraulic.

I got a flat-tappet cam, is there anything special I have to do with that? Someone told me I would have to add some zinc into my oil.

Just wear your damn mask...

> Bandit

Just wear your damn mask...

> Bandit

08/29/2013 at 23:19 |

|

BE VERY CAREFUL INSERTING THE CAMSHAFT

This isn't Prom night where you can just stick it in there and call it close enough. You can very easily nick one of those freshly installed cam bearings or - worse yet - something on your camshaft. And unlike Prom night, use lots of lube.

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/29/2013 at 23:23 |

|

Yes either the zinc additive or an engine oil with the zinc. Race oils usually has it in it. Check the label.

Bandit

> GasolineLollipop

Bandit

> GasolineLollipop

08/29/2013 at 23:27 |

|

Last thing, what are your opinions on these new fangled rubber freeze plugs?

My Autozone no longer carries the normal steel or brass type.

Audio Tachometer

> Bandit

Audio Tachometer

> Bandit

08/29/2013 at 23:51 |

|

Especially with a flat tappet cam, use a zinc additive. Use plenty of assembly grease. Keep everything CLEAN. Cleanliness is extremely important in rebuilding an engine. That can't be stressed enough. Rebuilding heads?

Bandit

> Audio Tachometer

Bandit

> Audio Tachometer

08/29/2013 at 23:55 |

|

I have new (to me) 6x heads to install. They look like they were rebuilt before they were put in storage or have very few miles on them, I don't plan on rebuilding them. The valves look perfect, there are no carbon deposits anywhere. Luckily the heads were built post-leaded fuel so I don't have to worry about that problem. They seem pretty good as far as free-to-me heads can go.

Any head installation tips?

Audio Tachometer

> Bandit

Audio Tachometer

> Bandit

08/30/2013 at 00:09 |

|

Heads are pretty simple. Make sure the rotating assembly is clean. Coat the cylinder walls with a THIN film of oil. Torque to spec in 3 steps. When that is done, go through and turn the engine with a wrench, putting your thumb on each of the spark plug holes. The compression should blow your thumb out of the hole. If not, something is wrong and should be fixed now rather than when it's all put in and runs like crap because one intake valve doesn't seat properly (or the like). If you aren't sure how to set valve lash, have someone help.

Bandit

> Audio Tachometer

Bandit

> Audio Tachometer

08/30/2013 at 00:11 |

|

Thanks! I never knew you could do a basic compression test with your finger.

Audio Tachometer

> Bandit

Audio Tachometer

> Bandit

08/30/2013 at 00:24 |

|

I just remembered that Chevys have hollow pushrods so put some oil in them. Get assembly lube in the rockers and top of the valve stems as well. The stuff under the valve covers doesn't get a lot of oil straight off.

Bandit

> Audio Tachometer

Bandit

> Audio Tachometer

08/30/2013 at 00:27 |

|

Will do! I have a Pontiac engine, but they are probably similar. What I am understanding here is "when in doubt cover in oil."

GasolineLollipop

> Bandit

GasolineLollipop

> Bandit

08/30/2013 at 09:38 |

|

I'd order brass freeze plugs if you can or check Napa or Carquest.

Audio Tachometer

> Bandit

Audio Tachometer

> Bandit

08/30/2013 at 17:49 |

|

Yep. Basically anything that can or will contact another surface gets oil or grease.